Tuesday, 5th December 2023

Centralised heating systems that supply heat to multiple buildings within a large multi occupancy building, large site or specific area utilise a central heat source.

Typically this maybe a combined heat and power (CHP) plant, a network of pipes to deliver hot water or steam to residential, commercial or industrial buildings. The centralised nature of such heating systems makes them highly efficient, as they allow for the utilisation of various heat sources, including renewable energy and waste heat.

Monitoring energy within centralised heating systems is important for several reasons, with a primary focus on optimising efficiency, reducing costs, and minimising environmental impact. Energy monitoring involves the collection and analysis of data related to energy consumption, allowing building or energy managers to make informed decisions and implement strategies for improvement and optimisation.

Having some form of energy monitoring in place provides real-time insights into the performance of a heating system. By analysing data on energy consumption, heat production, and distribution efficiency, energy mangers can identify areas where improvements are needed. Seasonal changes, varying demand, and other factors can impact the overall efficiency of the system, continuous monitoring helps maintain optimal operation under changing conditions.

Clamp on ultrasonic flow meters allow for instant flow meter readings to be taken at any point within a heating system (see our range of ultrasonic flow meters here). Due to their non-invasive technology a flow meter maybe installed on pipework within minutes and there is no direct contact with the fluid. This is advantageous because it minimises the risk of contamination, there is no pressure drop or disruption to the flow.

If the temperature differential is known between the heat flow and return pipe then an energy calculation can be made within the building management system (BMS). Alternatively an energy integrator maybe used to measure the temperature differential and accept an input from a flow meter to calculate the energy used.

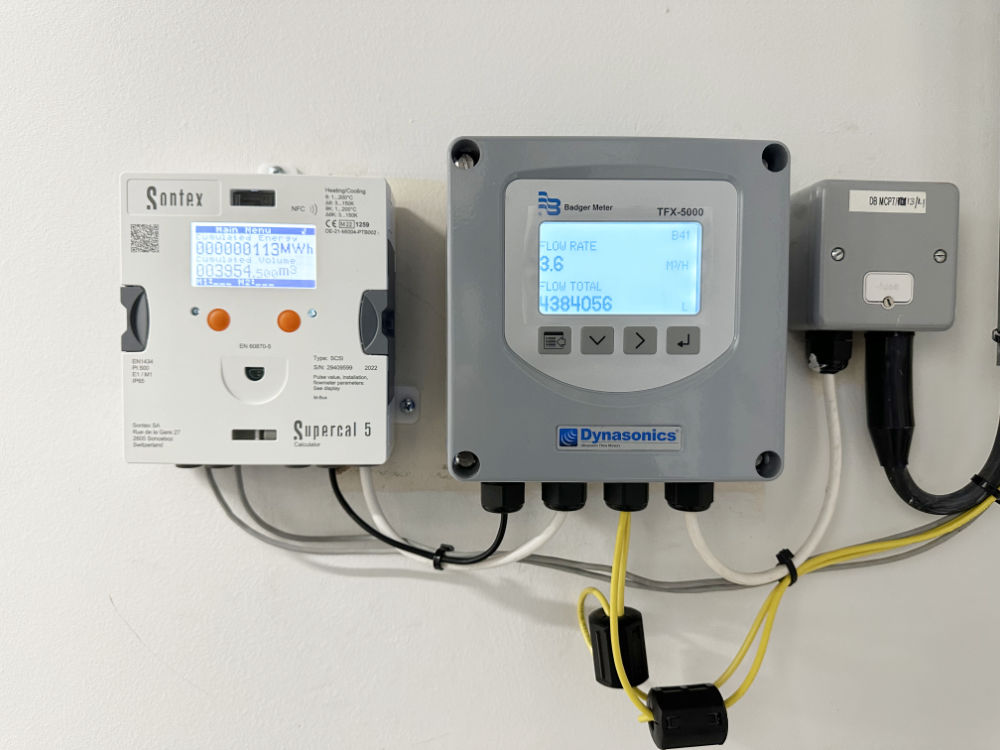

Below are photos taken from typical energy installations where clamp on ultrasonic flow meters have been retrofitted to existing pipework. These are then paired with energy integrators to provide energy calculations which are fed back into a building management system.

Dynasonics TFX-5000 measuring the flow rate on a LTHW pipe. Outputting a pulsed output for the “Flow Total” volume in litres. Typically this is programmed that 1 pulse = 100 or 1000 litres. The pulse input is received by the Sontex Supercal 5 energy integrator which also has PT500 temperature sensors measuring the flow and return temperatures. The display on the Supercal is showing the “Cumulated Energy” in MWh (Megawatt Hours) and the “Cumulated Volume” on m3 (Metres Cubed) for a defined period.

A typical installation of a pair of ultrasonic flow transducers installed within the Dynasonics Easy Rail mounting system. The Easy Rail is the “JZ” variant which is typically used on DN65 to DN150 sized pipes.

Below is an installation video for the Easy Rail system:

A closer look at the JZ Easy Rail mounting system. Typically on LTHW applications once the transducers are installed then the pipe lagging would be reinstalled around the pipe work for insulation.

Another example of the ultrasonic transducers installed on pipe work.

Another example of the Dynaosnics TFX-5000 ultrasonic flow meter working in conjunction with the Sontex Supercal 5 energy integrator. In this example we can see that the energy integrator is calculating the live power in kW (Kilowatts) of the heating circuit. Additionally it is calculating the flow rate of the heating system based on the time in which pulses are being received from the flow meter.

One of the key challenges for any heating system is the fluctuating demand for heat throughout the year. Seasonal variations, such as the transition from summer to winter, significantly impact energy usage. During colder months, the demand for heating increases, requiring the system to operate at higher capacities. Energy monitoring allows building managers to anticipate these seasonal shifts, adjust production levels accordingly, and ensure that the system meets the increased demand without overconsumption of resources.

Heating systems often experience peak loads during extreme weather conditions. Cold snaps in winter or unexpected temperature drops can lead to a sudden surge in demand for heating. Monitoring energy trends helps building managers identify peak load periods and implement load management strategies to balance the system. This proactive approach prevents system overloads, enhances reliability, and avoids unnecessary strain on the infrastructure.

Several factors may also influence energy usage within any heating systems, monitoring helps building mangers understand and address these variables effectively.

The energy efficiency of individual buildings connected to the heating system can vary. Monitoring allows for the identification of poorly insulated structures or those with inefficient heating systems, enabling targeted interventions to improve overall efficiency. Changes in building occupancy, such as holidays or weekends, can impact energy demand. Monitoring occupancy patterns provides valuable data for optimising energy distribution and adjusting production levels based on actual needs.

Heating systems increasingly incorporate renewable energy sources. Monitoring the contribution of renewables allows building managers to assess the environmental impact of the system and fine-tune the integration of sustainable energy sources.

Measuring energy within your heating system and sending data back to the BMS allows for trend data to be collated and understand the peak load requirements of any heating system.Having multiple energy meters across a heating system will allow bottlenecks to be identified within the system.

Dynasonics clamp on flow meters together with Sontex energy integrators allow for energy measurements to be made quickly and easily within heating systems.

Their wide range of application usage make them ideal for measuring low temperature how water (LTHW) as well as chilled water or water-glycol mixtures.

Additionally, one meter can be used across a range of pipe sizes for example a single meter can be programmed to be used across DN50 to DN300 pipes being compatible with many different types of pipe materials including copper, mild steel, carbon steel and stainless steel.

Various communications protocols are available with both the flow meter and energy integrator to allow data to be collected by a BMS. Protocols include:

In conclusion, monitoring energy usage within heating systems is an indispensable practice for optimising efficiency, reducing costs, and ensuring environmental sustainability. The ability to collect and analyse data on energy consumption, seasonal variations, and influential factors enables building mangers to make informed decisions and implement strategies that enhance the overall performance of the system.

Norfolk & Norwich use Portable Energy Meter from PCT

Premier Control Technologies are available to discuss your energy measurement requirements. Contact us today, by email on sales@pctflow.com or phone 01953 609930.

PCT are a leading UK distributor and your enquiry will be handled with the utmost professionalism. Please provide your details below.