Tuesday, 23rd January 2024

We supply a full range of Positive Displacement Pumps to cater for many industries; some of these include Biotech, Food and Beverage, Medical, OEM, Laboratorial and Analytical.

Deciding which Pump is best suited to help you with your application can be a daunting task, however PCT are fully equipped with the knowledge and experience to help you. Below you will find the different types of Pumps we supply, detailing some of their advantages and disadvantages. With over 50 individual pumps listed on our website, please do contact us should you need assistance.

| Principle | Pump Type | Main Wetted Materials | Max Flow | Max Pressure |

|---|---|---|---|---|

| FMI (Roper Technologies) | Valveless Piston Pump | PVDF, Stl Stl, Ceramic, ETFE, FFKM, Viton, PEEK | 4500 ml/min | 7 bar |

| Longer (Halma) | Peristaltic Pump | Silicon (most popular but other materials like Viton available) | 17000 ml/min | 2 bar |

| Longer (Halma) | External Gear (Micro Gear Pump) | PEEK | 2500 ml/min | 14 bar |

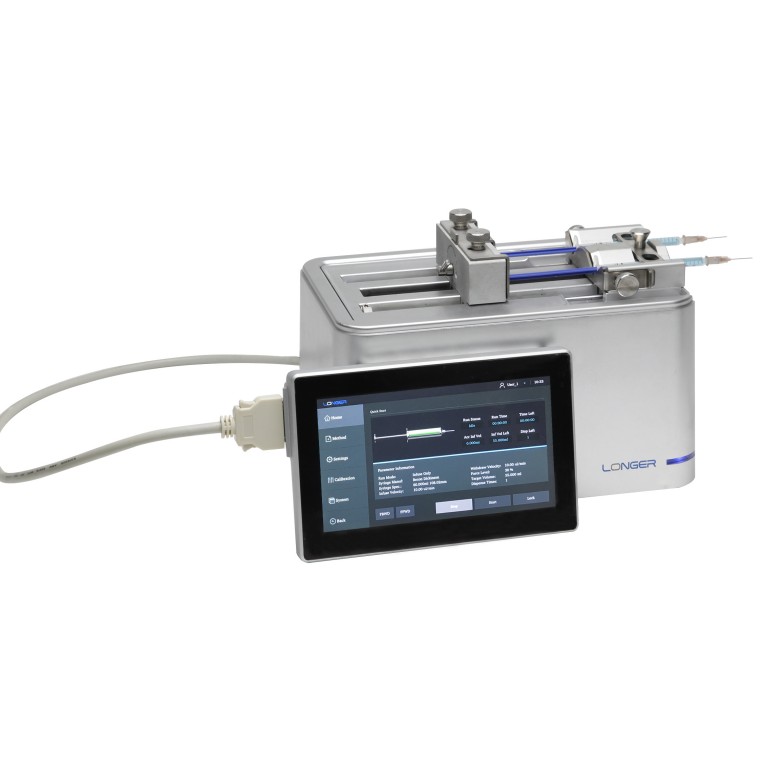

| Longer (Halma) | Syringe Pump | Polypropylene, glass (other materials available) | 50 ml/min | 3 bar |

| Advantages | Disadvantages |

|---|---|

| Very high accuracy and precision. 500 nanolitres per dispense up to 1.28 mL per revolution. CVs of 0.5% or better. | In a constant flow scenario, pulsation will occur, but it's not a concern in dispensing applications, and it can be effectively managed in constant flow scenario using a controller. |

| No valves (simple design). | Multiple wetted materials and seals are used. |

| Excellent suction capabilities. | It can operate dry but should not be run continuously without liquid for extended periods. |

| Self-priming design. | |

| Can be used with delicate fluids. The dispensing is gentle thanks to the low shear forces, making them suitable for use with cutting-sensitive fluids. | |

| Reversibility. | |

| Longevity and Durability. | |

| No need to recalibrate virtually removes a need for closed loop system (PID controller and flow meter). |

| Advantages | Disadvantages |

|---|---|

| The tubing is the only part of the pump that comes into contact with substance pumped and wears out and can be changed swiftly. | Due to the variability and flexibility of the tubing, the pump must be calibrated and recalibrated for high accuracy applications. |

| Excellent suction capabilities. | Due to wearing the tubing must be changed over time. If used extensively or without replacement, the tube may split or leak. |

| It works effectively for pumping small particles in suspension when they are smaller than 10% of the tubing's inner diameter. | Slight pulsation is inherent during operation but can be minimized by increasing the number of rollers, utilizing offset rollers, or employing the latest pulsation dampening technology like the Equlibar. |

| The lack of valves and seals/gaskets means less maintenance. | The flow rate will be effected by discharge and suction pressure. |

| It's a 100% self priming design. | The efficiency of peristaltic pumps will be affected by liquid viscosity, but the design can be modified to accommodate highly viscous substances, even up to 30,000 cps. |

| When the appropriate tubing is selected, peristaltic pumps are capable of handling highly corrosive and viscous fluids. | |

| They can also be employed with delicate fluids. Due to their low shear forces, peristaltic pumps are well-suited for dispensing sensitive fluids, ensuring gentle handling. | |

| Peristaltic pumps offer ease of cleaning and sterilization, ensuring minimal contamination. | |

| The pumps can operate without any time restrictions in a dry condition. | |

| Fully reversible, it functions effectively in both flow directions. |

| Advantages | Disadvantages |

|---|---|

| It maintains an exceptionally stable fluid stream with significantly lower pulsations when compared to other positive displacement pumps. | The pump cannot operate without the presence of the fluid; running it dry is not possible. |

| Relatively high accuracy. | Its not good with abrasive fluids and particles. |

| Reversibility means that the flow direction can be reversed. | |

| Excellent suction capability. | |

| Long lasting performance. | |

| Excellent sealing even in complex applications. | |

| Compatibility with high temperature variations, thus they can work with high and low temperatures. | |

| Good size to flow rate ratio. |

| Advantages | Disadvantages |

|---|---|

| No pulsation. | Need to refill the syringe after a dispense. |

| Highly accurate. |

Due to their design, our range of pumps are exceptionally versatile and suitable for a wide variety of applications. They excel in tasks involving fluid transfer or dosing, making them ideal for industries such as food, medical, and analytical applications.

In the medical field, our pumps are a perfect fit due to their compatibility and established usage with various types of fluids, regardless of their nature or viscosity. Moreover, we offer valuable assistance with validation procedures to ensure compliance with regulatory requirements.

Thanks to their precision, our pump range is widely adopted, even in industries dealing with inks, enamels, glues, and paints.

For water treatment applications, our pumps are suitable not only for handling chemicals used in treatments but also for liquids that are dense or contain suspended solids, without any risk of damage.

In the food and beverage industry, our pumps find extensive use in product pumping, transferring, and dosing tasks, including applications like flavour dispensing.

A 25-Step Guide to Peristaltic Pump Dispensing

Please do get in touch to discuss your requirements, call us on 01953 609930 or email sales@pctflow.com.

PCT are a leading UK distributor and your enquiry will be handled with the utmost professionalism. Please provide your details below.