Tuesday, September 17, 2019

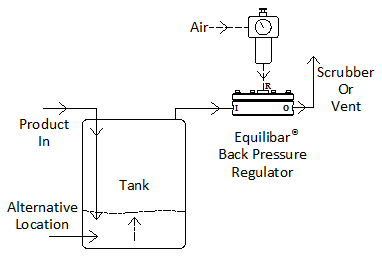

Many delicate fluids, liquid ingredients or slurry chemicals are transported and stored between process operations using pallet tanks or drums. These containers generally are designed for pressures up to 2 psi (.14 bar) and are often contained in a structural frame for easy storage and fork truck handling. The products within these containers often need protection from air and moisture to retain flavours and other properties, prevent oxidation and product deterioration with the typical solution being a blanket of inert gas. Challenges still remain, however, as emptying, filling and storage create a dynamic system. As the product is withdrawn from the container inert gas needs to added and controlled at a specific pressure. As the product is re-filled into the container the blanketing gas needs to have its pressure relieved with the resultant gas/product vapour mix needing to pass through a scrubber or recovery unit. Both of these processes, together with transportation and storage must be accomplished with the introduction of zero ambient air.

Connecting the tank to the dosing/filling system via an Equilibar back pressure regulator achieves the goal of retaining a slight pressure on the product container to retain shape and integrity whilst also relieving pressure as the container fills. Even though the flow rates required for these two actions are at quite some variance, an Equilibar GS series back pressure regulator copes admirably.

Or follow this link to view the full range of back pressure regulators.

SuperCritical Carbon Dioxide Pressure Control with Equilibar Back Pressure Regulators

If you would like to discuss your application please contact us.

PCT are a leading UK distributor and your enquiry will be handled with the utmost professionalism. Please provide your details below.