Tuesday, April 25, 2023

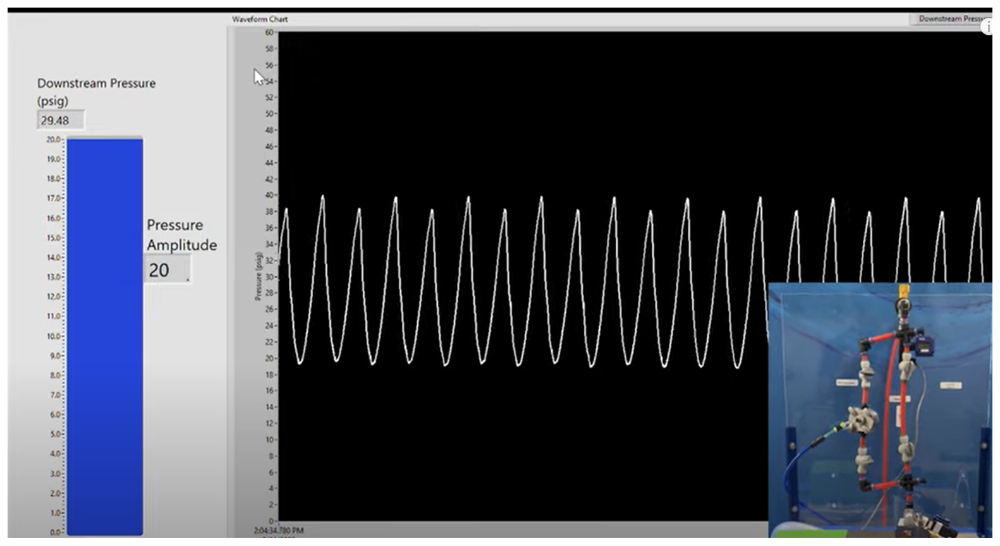

Peristaltic pumps generate pulsation as a consequence of their operational design. Peristaltic pumps utilize rollers or "shoes" to compress a flexible tube or hose, which results in the movement of discrete volumes of fluid through the tube in “pockets "created. When the rollers or shoes move away from the discharge side track after each volume of fluid is moved forward, the tube behind it expands to its initial shape, causing a temporary void that creates flow fluctuations or pulsation. The same phenomenon occurs on the suction side of the pump just in reverse. An example of this pulsation is shown below to demonstrate its potential magnitude:

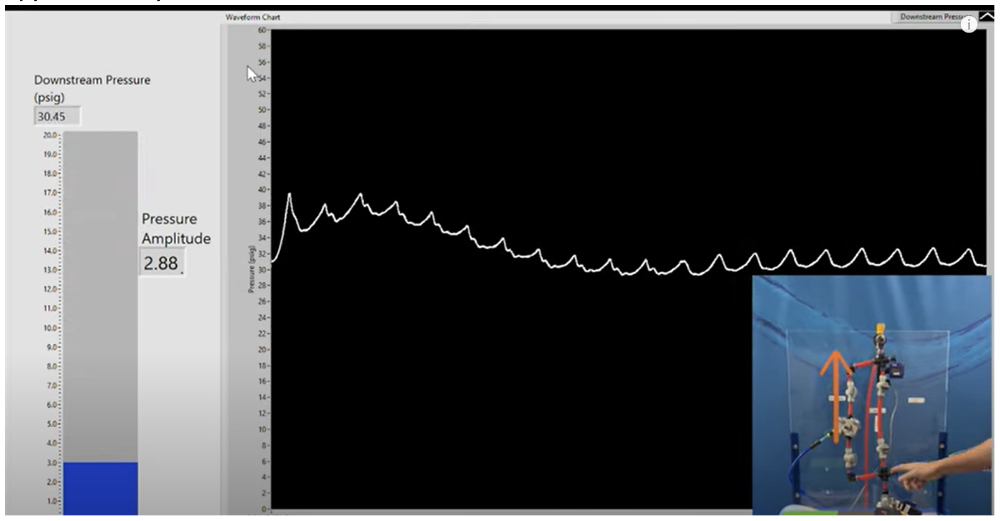

In the following screen shot, the peristaltic pump is depicted operating in conjunction with a c, specifically the Equilibar, which reduces the pulsation's intensity by approximately 10 times in this case:

Various factors influence the pulsation in peristaltic pumps, such as the speed of the pump, the elasticity and diameter of the tubing, the design of the track, the properties of the fluid being pumped, the number of rollers, and the rotor design.

Yes it can be, but in most applications it is not problem and in a few applications it it even a desired effect.

Pulsations associated with peristaltic pumps have the potential to compromise the integrity of the pumped product and can also place undue strain on the installed equipment. Depending on their severity, these pulsations can cause vibrating pipes and hoses, generate noise, and adversely affect downstream sensors, such as pressure or flow sensors, thereby hindering the accuracy of dosing and filling processes. In addition, pulsations can cause safety pressure switches to trip unnecessarily. Frequent exposure to vibrations resulting from pulsation can lead to the degradation of system components over time. Therefore, proper reduction of pulsation is necessary to increase the lifespan of the equipment.

The distinction between a pulsation dampener and an inlet dampener or stabilizer is solely based on their location within the system. When installed on the inlet or suction side of the pump, the device is referred to as an "inlet stabilizer," whereas installation on the discharge or outlet side of the pump would make it a "pulsation dampener." It's worth noting that peristaltic pumps can be bidirectional, and this reverses the naming depending on the flow path direction.

Using more rollers in a peristaltic pump head reduces pulsation. This is because the increased number of rollers results in smaller discrete volumes of fluid, thus reducing the size of the empty voids or "cushions/pockets" in between. This delivers more stable and consistent flow of the fluid. However, the frequency of pulsation will increase but will have smaller amplitude.

Although peristaltic pumps are generally less pulsatile than most positive displacement pumps, they still exhibit some level of pulsation. The special low pulsation offset peristaltic pump head design involves compressing twin tubes using offset tracks to split the inlet flow, generating two sets of pulses that are out of phase with one another. These channels are then combined at the discharge, resulting in the cancellation of one pulse by the flow of the other, which leads to a uniform and smooth outlet flow.

A pulsation dampener can absorb pulsation in a manner similar to how a car suspension system works. The dampener often consists of a rubber diaphragm that adjusts to the fluid and pressure levels in the system. When installed and calibrated correctly, a pulsation dampener can result in a steady fluid flow.

Equilibar BPR (back pressure regulators) uses thin diaphragms “loaded” with compressible gas, making the device more sensitive to small changes in pressure compared to traditional BPRs. Equilibar BPRs can react to changes as small as 0.01% of overall set-point.

Pulsation dampening is a natural quality of the Equilibar like traditional pulsation dampeners consist of a flexible membrane (typically rubber) with a pre-loaded air charge on the non-wetted side.

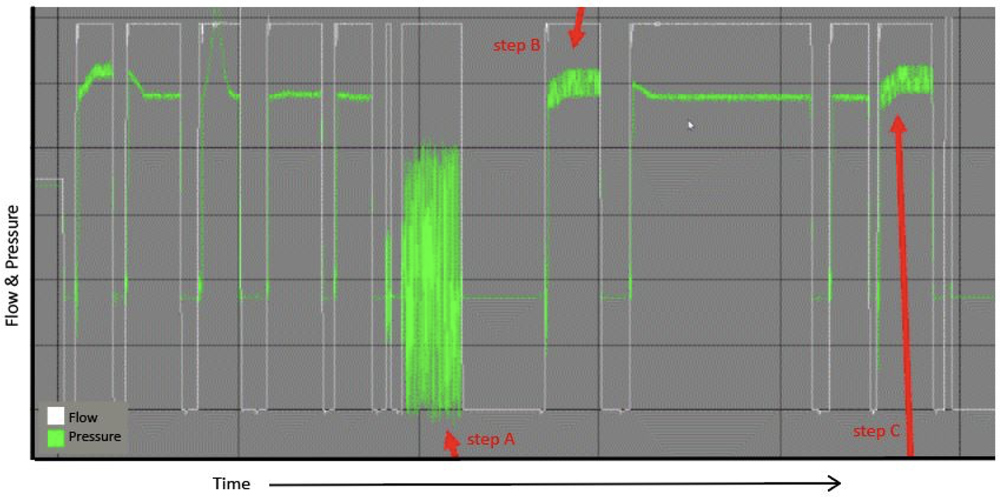

The ultra-wide Cv range of the Equilibar valve allows it to keep up with positive displacement pumps and diaphragm pumps to maintain consistent pressure during operation.

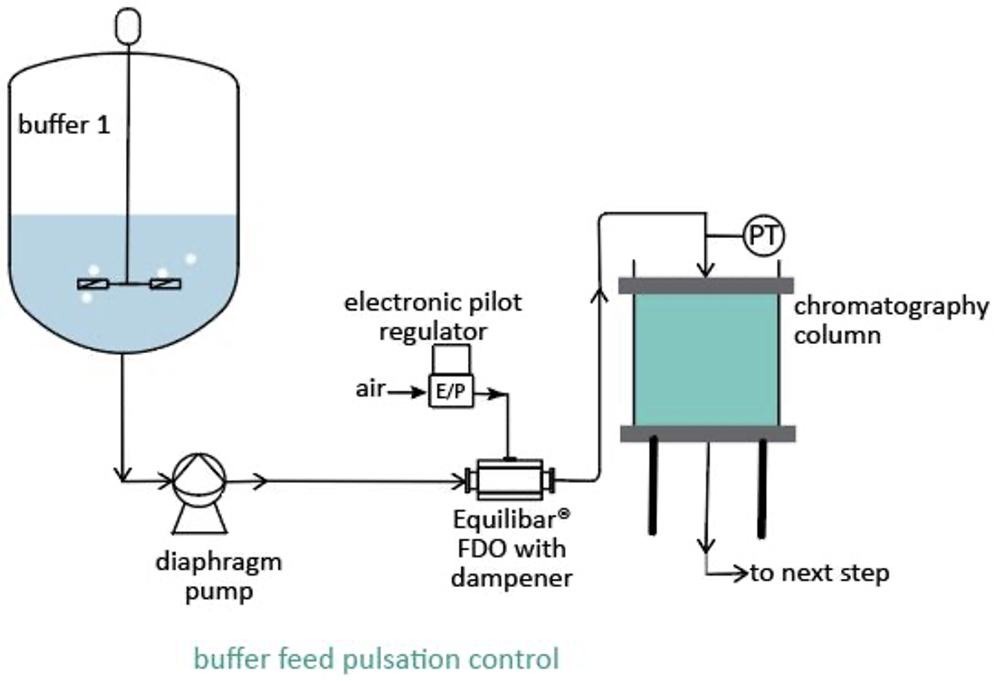

The product described in the diagram above is from our Equilibar Biopharmaceutical SD range.

Equilibar Saintary FD series valves and regulators are designed for use in sanitary applications where pulsations and shear stresses can have adverse effects on downstream processing and may even cause costly damage to the processed substance.

In bioprocessing, challenges often include the need to deliver fluids at precise flow rates across a wide range of flow rates, including very low flow rates. Additionally, positive displacement pumps used in bioprocessing can create pulsations that must be eliminated, and consistent back pressure is needed to prevent bubble formation.

Equilibar BPR is equipped with both passive and active pulsation dampening features for downstream applications. Passive dampening inserts are used to minimize pressure pulsations downstream, and the BPR's active pulsation dampening feature further ensures a steady flow.

If you have any questions or would like to discuss you specific application please feel free to contact the team.

PCT are a leading UK distributor and your enquiry will be handled with the utmost professionalism. Please provide your details below.