The Alicat Scientific range of CODA Coriolis Flow Meters and Controllers are ideal for the precise and accurate measurement and control of gases and liquids in low to ultra-low flow regimes. Due to the very high turn-down ratio (overall measured range) only three models are required to cover flow from 0.2 grams per hour through to 30,000 grams per hour (30 LPH). The standard instrument is pressure rated to 500 psia (34 Bar) although there is the option to increase this to 3500 psia (240 Bar) with wetted parts being 316L stainless steel (Hastelloy C as another option). Fluid density is measured over the range of 0.2 to 2 g/cc to an uncertainty of +/- 0.005 g/cc. CODA is therefore a tightly packed solution for both Mass Flow and Density.

Fill out the Configurator Form so our engineers can craft the perfect custom solution for you:

Configure nowOne way to visualize the Coriolis Force is to take a hose-pipe and lay it out in a straight line down your garden. When you switch on your tap the water, obviously, comes out of the end. If you now put a loop into it and turn on again the hose-pipe snakes around with a life of its own. This is because the water is exerting a Coriolis Force onto the pipe.

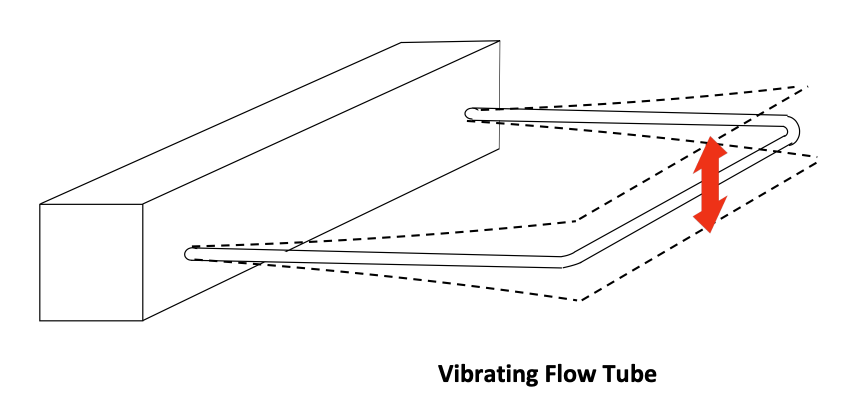

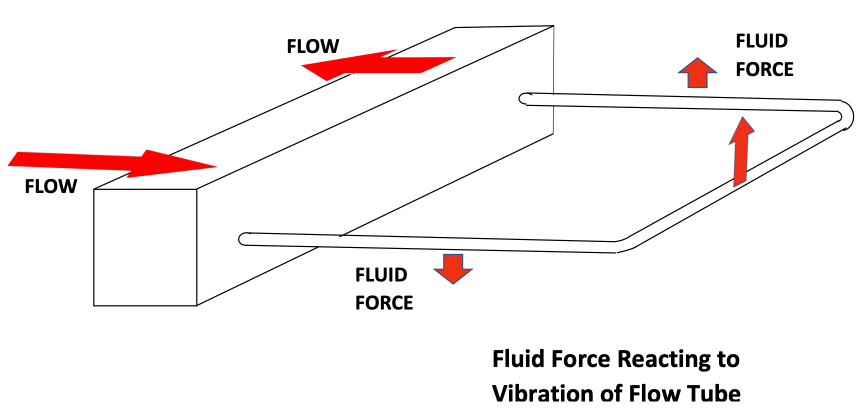

A Coriolis flow meter also contains a tube, although this one is square shaped and energized by a fixed vibration. When the water (or indeed another fluid or even a gas) passes through this tube the force of the mass flow will cause a change in the tube vibration and the tube will slightly change its shape resulting in a phase shift. This phase shift is measured using an optical sensor and since the relationship is linear a usable straight line output can be derived that is proportional to the mass flow. As this principle measures mass flow it is therefore independent of whatever is flowing within the device i.e. independent of the fluid properties and as such can be directly applied to liquids or gas, blends or mixtures included.

Furthermore, in addition to the phase shift in frequency along the length of the sensor tube the device can also measure the actual change in natural frequency. This change in natural frequency is now in direct proportion to the density of the fluid and a further usable straight line output signal can be derived.

Due to the advanced design of Alicat Coriolis Instruments, the higher operating frequency and very light mass of the vibrating tube, they are not affected by pipework and/or base-block vibrations. They therefore do not require the additional costs of either high mass blocks or dampeners.

Both the meters and the controllers are small in size and are therefore ideal for lab-space, fume cupboards, compact pilot rigs and OEM applications within other equipment.

Meter dimensions: 70mm x 30mm x 100mm (L x W x H)

Controller dimensions: 90mm x 30mm x 100mm (L X W X H)

Due to the highly stable zero and the clarity of internal signals our Alicat Coriolis instruments can measure far down into their flow curve.

Furthermore, as the accuracy statement is based on a percentage of the measured value measurement uncertainty remains incredibly low across the whole flow range. The benefits are numerous – fewer instruments are required, simpler pipework can be installed and fewer spares are required – all designed to reduce costs and increase quality.

As mentioned above, the stability of the zero point ensures that the device can measure far down into its flow curve. In addition, this capability also ensures that an Alicat Coriolis instrument is highly repeatable from one device to another – essential for example in comparative chemistry when numerous cells are run in parallel.

The measuring principles of Alicat Scientific Coriolis instruments are based upon a specific geometry of sensor tubing that is energised by a constant fixed vibration. When the process fluid, either gas or liquid, passes through this sensor the force of the flow will cause the vibration to change and the tube to very slightly change shape. This will cause a phase shift in the vibration, the extent of which is directly proportional to the mass flow.

This same measurement technique mentioned above also ensures that CODA Coriolis instruments measure the mass of the fluid independent of the fluid properties. In this way it is still possible to measure the mass flow of mixtures and blends of fluids with an unknown variation or concentration. Coriolis, as well as other solutions, can also assist with variations in density and temperature, temperature and pressure and temperature and viscosity.

Where the differential across a traditional control valve is too high we are able to integrate our Coriolis device together with an Equilibar valve. In liquid applications this will need to be achieved via a separate dome loading gas supply, however, when the process gas is appropriate it is possible to use the pressure loss across the Coriolis as sufficient drive to dome-load the Equilibar.

With the Meter only requiring 1.4W (58 mA at 24 Vdc) and the Controller only requiring 4W (16 mA at 24 VdC) Alicat Coda require only a low power requirement – making life easier for system design engineers and running costs lower for the end user.

Applications for Alicat Coriolis Meters and Controllers are present throughout a vast number of industries especially when considering the benefit of direct pump control assemblies and systems (direct control offers highly precise pump speeds, auditable data logging, non-pressurized chemical storage and pump condition monitoring to name but a few).

| Market Group | Market Segment | Applications |

|---|---|---|

| Applied Science | Semiconductor | Precursor Flow Control Etch Control |

| Nanotechnology | Nano-flow control Liquid Dosing Micro-Reactors | |

| Glass Production | Spray Coating Surface Conditioning | |

| Surface Treatment | Vapour Control Polymer Spraying | |

| General Industry | Chemical | Pilot Plants Out-gas Flow Measurement Catalyst Addition Solvent Delivery |

| Food / Drink / Brewing | Natural Flavour Additives Vitamin Dosing Colourant / Aroma Addition Disinfectant Dosing | |

| Specialty Gas | Gas Mixture Measurement | |

| Water | Treatment Chemical Dosage | |

| Household Products | Colourant Additives Fragrance Additives | |

| Energy | Natural Gas | Odorization Control |

| Fuel Cell | Humidification Process Gas Mixture Measurement | |

| Biofuel | Additive Dosing Calorific Value Boosting | |

| Solar Cell | Etch Control Deposition Control | |

| Life Science | Pharmaceutical | SCCO2 Control H2O2 Control Micro-Fluidics |

| Biochemistry | Scaffold Manufacture Solvent Control | |

| Biotech / Bio-Reactors | Liquid Dosing | |

| Medical | Rapid Calibration Device Back up to Syringe Pumps | |

| Analytical | Analyzer Manufacturers | Nanoflow Pump Control Calibration Gas Production Liquid Mixture Flow |

| Intellectual | Universities | A great many applications exist across science and engineering |

| R&D Facilities | ||

| Technical Institutes |

My experiment produces a mixture of gases at an unknown composition. Will Coriolis work?

Unlike thermal mass flow devices, that need to know the proportion of components in a gas, Alicat Coriolis flow meters directly measure the mass of the gas regardless of its make up. By also measuring the density of the gas it is also possible to calculate the volumetric flow.

My laboratory has a strict approach to potential hazards so we are not allowed to have pressurized containers of liquid – even in the fume cupboards. How can we apply a motive force to be able to control the flow?

By utilizing the on-board PID control, and sending a proportional output signal, it is possible for an Alicat Coriolis device to directly control the speed of, for example, a micro-gear pump to achieve the pulse-less continuous flow rate. Suction by the pump can be from a non-pressurized container. A given flow rate will require a certain speed by the pump and this is controlled by a signal from the flow meter. Over time there will inevitably be wear on the gears and the pump will need to increase its speed to still generate the same flow. By monitoring the control signal a trend over time can be established and preventative maintenance initiated if required. In the meantime the flow rate has remained precisely constant.

At the end of our filling process we wish to repetitively dose 10cc of aroma additive into five different injection points. Can this be done accurately?

Having a single Coriolis instrument set up as either a controller, or with pump control, or with an on/off valve with five parallel outlets it is possible to achieve this. As long as the five parallel dosing lines are of equal length and with the exact same geometry an acceptable level of accuracy can be maintained.

We operate in a highly regulated environment and all fluid transfer needs to be data-logged in case of future audit. How can this be ensured?

Again, by linking the Coriolis meter to such pumps as peristaltic pumps, syringe pumps, gear pumps or diaphragm it is straight forward to control the flow rates required. Not only does a control signal directly control the pump but a measured value output signal can be collected by the data-logging program. The pump condition is therefore logged, as is the actual amount of fluid transferred.

Our process fluid is not only highly corrosive but also runs at between 100 and 150 bar. We also require a very wide range of flow rates. Is something in Hastelloy C possible?

Yes, not only can the Coriolis sensor itself be made of Hastelloy C, a control valve with Hastelloy C wetted parts can be integrated. Please refer to our Equilibar page.

KROHNE's OptiMass range of Coriolis flow meters provides class-leading accuracy for liquid and gas mass flow measurement.

Both straight tube and conventional Coriolis models are available in the range dependant on your process and application.

Various electronics options are available for compact mount and remote field mount electronics with class leading accuracy.

Krohne's OptiMass flow meters are ideal for process applications and custody transfer (CT) applications. Mass, volumetric flow, density and concentration measurement of liquids and gases.

The optimass range is ideal for applications which may require hazardous certification or SIL functional safety. Specific certifications are available for hygienic applications or the marine and nuclear industries.

Krohne’s Optimass are high performing flow meters for use in a wide variety of industries and are manufactured here in the UK.