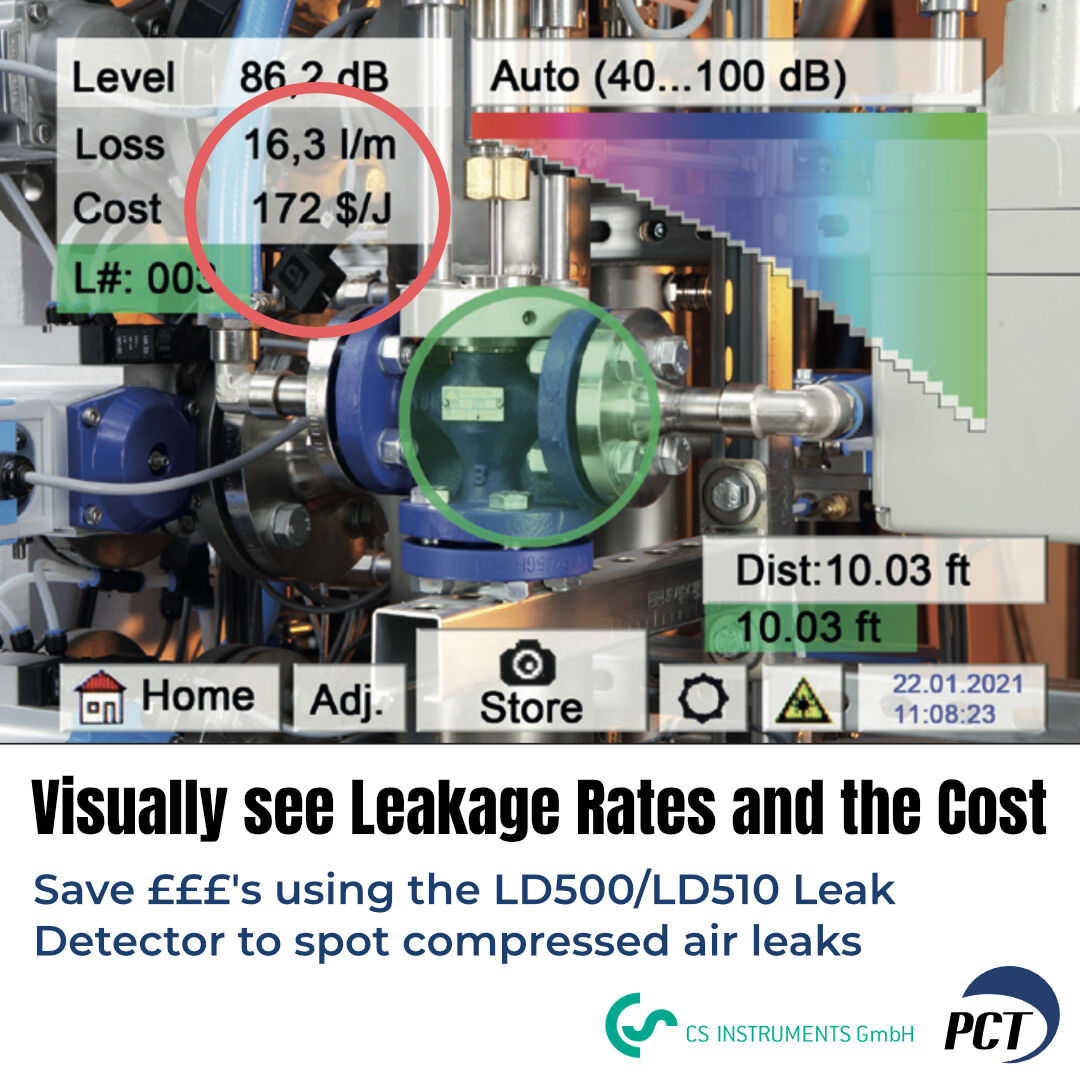

CS instruments LD range of handheld compressed air leak detectors can not only detect leaks in compressed gas pipe work but they can also calculate the costs these leaks will cause over time.

Compressed air is used in nearly every industrial application as over 80% of production processes use compressed air at some point in their system. Compressed air systems must be extremely efficient as they account for approximately 10% of all industrial electric consumption.

Energy is the main cost for those operating a compressed gas system and accounts for 73% of all energy consumption. Inefficiency within compressed gas systems is common with the main causes being leakages, over pressure in the system and heat recovery. Identifying and fixing leaks are the largest potential savings during the process at 42%.

According to investigations and research, leakage rates of 30% are not uncommon which results in a pressure loss of up to 2 bar and 50% of energy being wasted and unused.

Flow measurement, analyse measured data detect for leakages, document, and quantify leakages.

The CS Instruments leak detection range allows for optimal identification of leaks and along with the CS leak reporter software helps to manage and track leaks within the production line. The hand-held detectors identify leaks by measuring the ultrasound emitted from the leak sites allowing for precise detection.

Once leaks are detected they can be photographed, the annual cost of the leak calculated and can be stored into the system with a location, priority, and date. Leaks can be uploaded to the Leak Reporter software and access maybe granted to both on-site and off-site users. The range of detectors feature many measuring accessories that provide long and short-range leak locations. This provides a greater advantage in locating leaks then other methods such as leak detection spray.

CS Instruments leak detectors can be used within processes, applications or sites which contain other gases than compressed air. That includes nitrogen (N2), argon (Ar) or oxygen (O2) systems

Leaks can be reported according to ISO 50001 with optional cloud-based logging of leaks for use on large systems and sites.

| Display | 3.5" colour display and touch panel |

| Audio | 3.5mm headphone jack and soundproof headphones |

| Software | USB connection to connect with reporting software |

| Output readings | Can show volume of leakage and approximate cost of leakage per year (see red circle in diagram below) |

| General | Laser and integrated camera |

Leakages can be saved and have photographs taken of them and given a leak identity number and can have a tag placed on that area of the compressed air system. Leaks can be classified under company name, building, location, error description and what priority the leak is.

USB connectivity allows transfer of leak data and photos over to recording software. Reports come with a photo, date/time, description of the position of the leak, size of the leak, cost of leak using energy and size of leak inputted by the user.

| Acoustic trumpet | Ideal for everyday leak detection where the range is easy to reach (within 20 cm to 5m) |

| Parabolic mirror | Leaks can be located to within 15cm from a range up to 15m |

| Gooseneck | Finds leaks in hard to reach areas with low sensitivity to allow for more precise locating of leaks. Length of tubes are 0.6m and 1.5m |

| Straightening tube with tip | Allows for checking on multiple leaks within a small area |