The range covers general dew point measurement for all kinds of driers and extends to harsh or industrial environments as well as portable applications. Most devices are suitable for a wide range of gases such as compressed air, oxygen, nitrogen and argon.

Dew point can be defined as the temperature the air needs to be cooled to (at constant pressure) in order to achieve a relative humidity (rH) of 100%. At this point the air cannot hold more water in the gas form.

Absolute humidity is the actual amount of water vapour present in the air, it is independent of the temperature. Absolute humidity is expressed as moisture per cubic meter of air (g/m³).

Max humidity is the maximum amount of water vapour present in the air at a certain temperature. This value will change as when air becomes hotter it can hold more moisture. Maximum humidity is also expressed as moisture per cubic meter of air (g/m³).

Relative humidity is the ratio of the absolute to the maximum humidity. It is expressed as a percentage commonly % rH.

The diagram below should help us understand a little more:

The table below also helps us calculate the relative humidity. If we are able to measure the humidity in the air and we know the temperature of the air we can then calculate the relative humidity.

For example, if we measure a humidity value of 4000 g/m3 and we know the air temperature is 0℃ then we can calculate the relative humidity to be 97.8%

| Temperature ℃ | Max Humidity (10-3 kg/m3) |

| -25 | 0.64 |

| -20 | 1.05 |

| -15 | 1.58 |

| -10 | 2.31 |

| -5 | 3.37 |

| 0 | 4.89 |

| 5 | 6.82 |

| 10 | 9.39 |

| 15 | 12.8 |

| 20 | 17.3 |

| 30 | 30.4 |

| 40 | 51.1 |

| 50 | 83 |

| 60 | 130 |

You can visually see water condensing in the air, when we take a cold drink out of the fridge sometimes we can see water forming on the outside of the drink. The outside of the drink will cause water to form on the surface if it is below the dew point of the ambient air. The moisture in the air forms on the surface of the drink.

At the dew point temperature, the relative humidity (rH) is always 100%. The graph below outlines that as the temperature and dew point increases the maximum humidity increases exponentially.

Pressure will effect dew point, the term atmospheric dew point refers to the temperature at which the water vapour in the air reaches a maximum saturation without the influence of an external pressure source. Atmospheric dew point is important for aviation and metrology where it aids pilots and forecasters for predicting weather patterns.

Pressure dew point is measured within an air compressor unit at a temperature greater or less than the atmospheric air pressure. It is the temperature to which the compressed air can be cooled down without any condensation. The pressure dew point will depend on the final compression pressure. This measured temperature is critical in monitoring the water vapour saturation levels of the air being compressed. Both atmospheric and pressure dew point use the ℃td symbol which references the atmospheric dew point.

The diagram below helps us to visualise the difference pressure makes on dew point. When the pressure condition is at atmospheric (1 bar absolute) we can see that the dew point is at 5.15 ℃.

When the air volume is compressed to 2 bar absolute (1 bar gauge) the partial pressure of the contained water vapour increases, the dew point increases to 15.54 ℃.

The ambient air can be imagined like a wet sponge, in a normal condition it is able to absorb a certain amount of water. If the sponge is squeezed part of the water drops out of it.

Our range of dew point measuring sensors from CS instruments are ideal for compressed air applications, in fact they have been specifically designed for use within compressed air systems.

Sensors are available for permanent installation applications or where a portable dew point measuring device may be required. Installed meters can be used both for indoor and outdoor environments as well as hazardous environments where an Atex certified dew point meter is required. Further to this all our CS dew point sensors can be paired with their own chart recorders to allow for trend data to be captured.

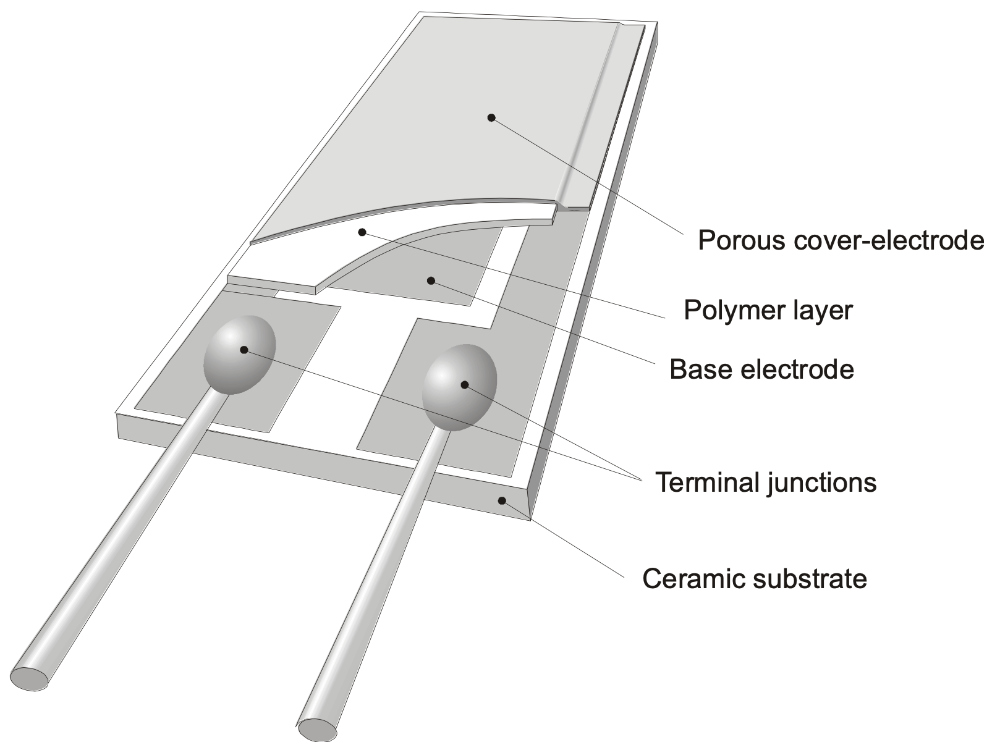

CS instruments sensor technology uses a polymer capacitive sensor where the adsorption of water results in a capacity change of the sensor.

The polymer layer protects the sensor from any dust, oil or condensate in the case of dew formation and other foreign objects within the process. Unlike differing sensor technologies, the sensor can easily be removed from the process and cleaned should this be required.

Devices can output a wide range of data over digital communications from the sensor including:

Take time to view this 46 minute long video explaining the importance of Dew Point measurement and how it can help prevent production issues for your process.