We aim to respond within 1 hour

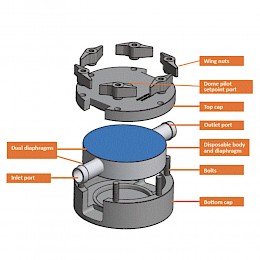

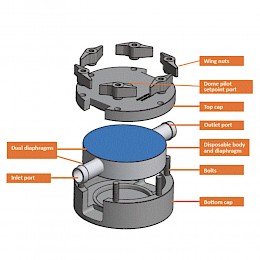

Sanitary SD Series back pressure regulators from Equilibar have been developed in single-use design to accommodate the rapidly expanding requirements of the biopharmaceutical industry. Two vital features have been adopted as these are crucial to the concept; firstly, that the components are low cost and secondly that they can be sterilized through irradiation and disposed of safely after use.

The Sanitary SD Series are manufactured using USP Class VI polymers for both the body and the diaphragm together with 316 Stainless Steel for the support housing.

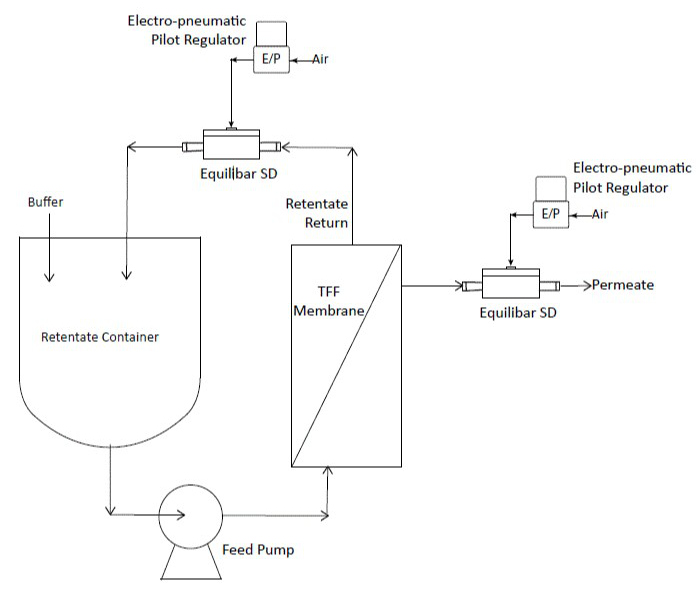

The Equilibar SD is a dome-loaded pressure regulator with pilot operation. Inert gas or air is fed into the pilot port on the dome of the regulator to provide the pressure setpoint in a 1:1 ratio for the process. The pressure of the gas in the dome is set by a secondary standard regulator called a pilot regulator. The pilot regulator can be manual or electronic depending on the application’s requirements

Equilibar regulators feature ultra-sensitive diaphragm-operated back pressure technology capable of controlling pressure with high precision over a wide range of flows. The Biopharmaceutical SD valve has negligible hysteresis and provides excellent stability.

Equilibar regulators respond instantaneously to variations in flow or changes in setpoint to maintain the desired inlet pressure. Due to this ultra-fast control capability, the Biopharmaceutical SD Series is a perfect match for computer automated control. Paired with an Alicat electronic pilot regulator, the Biopharmaceutical SD valve can be connected to the process control system making it ready for automation within numerous industrial protocols.

The disposable parts of the Equilibar SD valves are manufactured and packaged in a class 7 clean room and shipped in hermetically sealed plastic bags ready for sterilization.

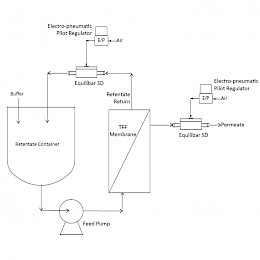

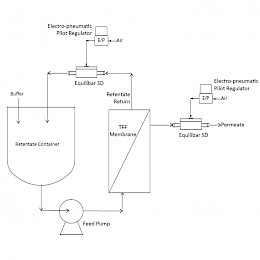

Tangential flow filtration, or TFF, is used in the biopharmaceutical industry as an efficient ultrafiltration method for purifying biomolecules. During the process, the differential pressure across the TFF membrane must be maintained within a narrow range, in some cases as low as 1 psi. The Equilibar SD delivers superior precision and can accurately control transmembrane pressure in a wide range of flow rates. In the Figure at left, Equilibar SD valves are installed in both the retentate and permeate lines of the TFF process. Using electronic pilot regulators, setpoints are established to the domes of the SD valves to deliver the desired TFF transmembrane pressure differential. The SD valves are able to adjust quickly to changes in upstream pressure or flow in order to maintain stable target dP for effective TFF process control. The SD regulator may also be used in other downstream ultrafiltration processes where precise pressure regulation improves process performance.

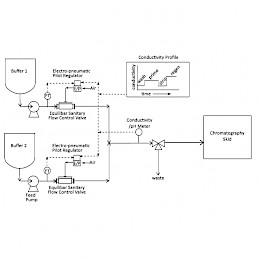

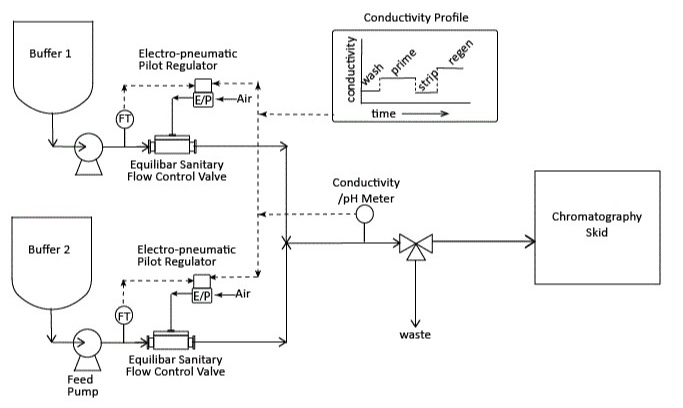

A "gradient elution skid" or "gradient buffer skid" upstream of the chromatography skid adds buffers at varying ratios and specific timing to perform the gradient chromatography process. Multiple buffer solutions are stored on the gradient elution skids and delivered via feed pumps to the chromatography column based on a pre-set conductivity profile specific to an elution process. The Equilibar SD can act as a flow control valve, delivering precise blending with its millisecond response to changes in the conductivity profile setpoint. The immediate response of the SD regulator controls the upstream process quickly, delivering cost savings due to less waste. The Equilibar SD can maintain consistent flow over a wide range of flow rates, resulting in fine blending for a variety of pharmaceutical blending processes. Commonly, a flow turndown of 100:1 is possible using the SD valve, which covers a range equivalent to four standard control valves.

Fill out the Configurator Form so our engineers can craft the perfect custom solution for you:

Common process applications and industrial uses include:

Relevant article:

Port sizes:

Additionally:

The Biopharmaceutical SD Series is widely used in the following industries:

We aim to respond within 1 hour

Call us

01953 609930

Email us

sales@pctflow.com

Please provide your contact details below.

PCT are a leading UK distributor and your enquiry will be handled with the utmost professionalism. Please provide your details below.