Click the link below to request a quote for your system.

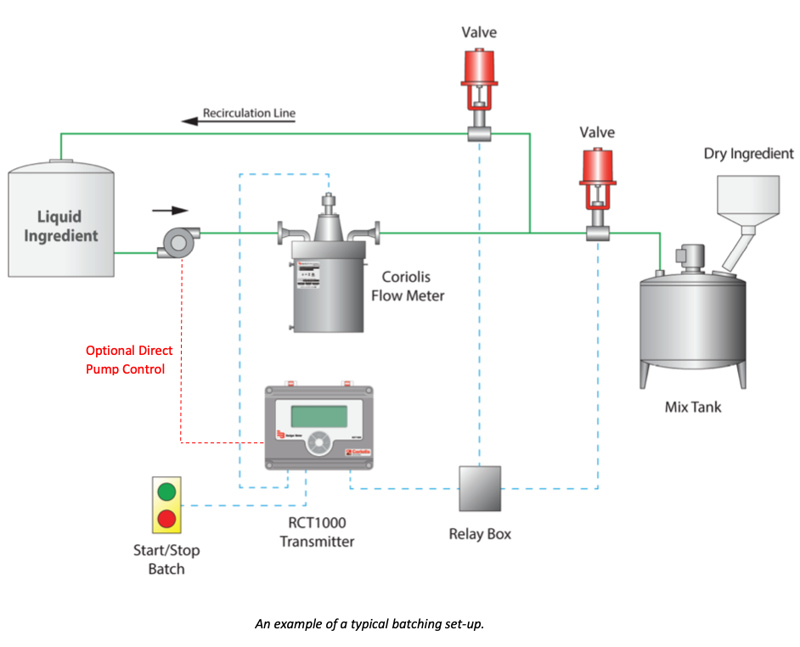

Request a quote / infoCoriolis flow meters can achieve batch control by linking measured value inputs with various control signal outputs. A specific discrete batch or dosage can then be released by opening or closing valves or, with the use of the on-board PID loop, by directly controlling the proportional speed of a pump. The easy-to-use accompanying software can be installed on a computer that connects to the Coriolis transmitter via the USB programming port. In addition to meter configuration, the software provides logging, trending and diagnostic capability for the measured values. There are a number of batching options which, for most applications, eliminate the need for a separate batch control device. These features are user-selected via the Coriolis transmitter keyboard and include:

When the batch starts (T0) the Status 1 output turns on thereby engaging the pump or opening the valve. When the measured batch total matches the batch setpoint then this output is turned off thereby stopping the pump or closing the valve. Typically, there is some lag in the process before the flow is fully stopped. In simple stop/start batching this overrun quantity is not included in the batch total. There are ways to overcome this.

Flow End Batching operates the same as the simple start/stop batching except the overrun quantity is included in the batch total.

Diverter Batching requires a 3-way valve or flow diverter. When the batch is stopped, the fluid is diverted into a recirculating loop and the fluid continues to flow through the meter, but not into the container. The batch total only accumulates while the output is ON, although fluid continues to flow through the meter.

If the overrun flow is significant, you can set a pre-trigger to turn the output off early to reduce the amount of overrun. The pre-trigger can be time-based or quantity-based.

The time-based pre-trigger is most often used when the process system has a consistent response, such as the time for a valve to close, and the flow rate is constant during the batch but not necessarily the same between batches. The transmitter calculates the amount of mass or volume that will continue to accumulate by multiplying the flow rate and the time pre-trigger.

If the flow rate is consistent across all batches, it may be easier to use the quantity based pre-trigger.

For Start/Stop or Flow End Batching, the pre-trigger does not affect the batch total. For Diverter Batching, the quantity defined by the pre-trigger is added to the batch total when the batch output is turned OFF.

In Two-Stage Batching, fluid flows through a valve that has three positions: fully open, low flow and closed. In effect it is possible to have “fast fill” followed by a “top-up fill” that not only minimizes batch overruns but also eliminates water hammer that may damage equipment (including the Coriolis meter) over time.

Within batching, dosing and filling applications there are clear benefits by close-coupling and directly driving the speed of a pump. These benefits can be seen in four specific areas:

Accuracy: The actual output of the pump is measured and controlled to exactly the required amount.

Performance: More stringent process control ensures that increased repeatability, increased quality and improved yield. At the same time product rejects are decreased as is wastage and lost time and cost due to re-work.

Mechanical Reliability: The control signal between the Coriolis meter/transmitter and the pump can be logged, trended over time and set with shell alarms to alert for both process upsets and efficiency change. As an example, as the gears in a gear pump wear over time the speed of the pump needs to progressively increased to achieve the same flow rate. The corresponding increase in the control signal can be monitored and used in the decision to commence preventative maintenance.

Accountability: Within high product value or sensitive applications both live dosage rates and individual batch totals can be measured and data-logged for accountability purposes.

Premier Control Technologies have the expertise to control from 0.03 kg/hour through to 140,000 kg/hour and particular specialism with viscous fluids and slurries.

Here is a general article we have written introuducing Premier Control Technologies (PCT) and our systems: Premier Control Technologies Systems

PCT are a leading UK distributor and your enquiry will be handled with the utmost professionalism. Please provide your details below.